- 927 Lee Road 268, Valley, AL

- 256-790-9771

Spray Foam Insulation Attic Insulation Services by Pro Insulations

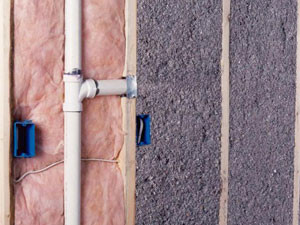

Pipe & Cellulose Insulation Services in East Alabama & West Georgia: Save Energy & Reduce Heat Loss

Pipe & Cellulose Insulation Services in East Alabama & West Georgia: Save Energy & Reduce Heat Loss

Cellulose Insulation Products

Four major types of loose-fill cellulose products have been developed under a variety of brand names. These are generally characterized as dry cellulose, spray applied cellulose, stabilized cellulose, and low dust cellulose. These types are used in different parts of a building and for different reasons.

Dry cellulose (loose fill)

Dry cellulose is used in retrofitting old homes by blowing the cellulose into holes drilled into the tops of the walls. It can also be blown into a new wall construction by using temporary retainers or netting that is clamped in place then removed once the cellulose has reached the appropriate density. This form of application does settle as much as 20% but the stated R-value of the cellulose is accurate after settling occurs. In addition, a dense-pack option can be used to reduce settling and further minimize air gaps. Dense-pack places pressure on the cavity, and should be done by an experienced installer.

Loose fill in walls is an antiquated technique of using cellulose in wall cavities. The home performance industry and its accrediting bodies support the dense-pack standard of insulating wall cavities, which does not settle. This method stops the stack effect and convective loops in wall cavities.

Spray-applied cellulose (wet-spray cellulose)

Spray-applied cellulose is used for applying cellulose to new wall construction. The differences are the addition of water to the cellulose while spraying as well as adding some kind of moisture retardant such as chlorine to prevent mold cultures. In some cases the insulation might also mix in a very small percentage of adhesive or activate a dry adhesive present in the cellulose. Wet-spray allows application without the need for a temporary retainer. In addition, wet-spray allows for an even better seal of the insulated cavity against air infiltration and eliminates settling problems. Wet-spray installation requires that the wall be allowed to dry for a minimum of 24 hours (or until maximum of 25% moisture is reached) before being covered.

Low-dust cellulose

The last major type of cellulose insulation on the market is low-dust variety. Nuisance levels of dust are created during application of most types of dry insulation causing the need for simple dust masks to be worn during installation. This kind of cellulose has a small percentage of oil or similar dust dampener added. This may also be appropriate to homes where people are sensitive to newsprint or paper dust (though new dust will not be created after installation).

Stabilized cellulose

Stabilized cellulose is used most often in attic/roof insulation. It is applied with a very small amount of water to activate a type of adhesive . This reduces settling and decreases the amount of cellulose needed. This can prove advantageous at reducing the overall weight of the product on the ceiling drywall helping prevent possible sag. This application is ideal for sloped roofs and has been approved for 5:12 (41.66%) slopes.

Make the jump to energy efficiency today!

Spray foam insulation is the best choice for energy efficient insulation in your new or existing home.

Call us today

Advantages Of Cellulose Insulation

When it comes to insulating their homes, homeowners have many good choices. One option to consider is cellulose insulation, and it passes as a strong contender. Tightly packed cellulose provides a thermally efficient, cost effective and comfortable solution. Cellulose is made of 80% recycled newsprint which is chemically treated to resist fire, insects and mold. It’s no wonder that experts consider cellulose to be safe, “green” and efficient.

Best Service In the industry.

Make the jump to energy efficiency today!

Spray foam insulation is the best choice for energy efficient insulation in your new or existing home.

Call us today

When Should You Need a Radiant Barrier?

A radiant barrier works best when it is perpendicular to the radiant energy striking it. Also, the greater the temperature difference between the sides of the radiant barrier material, the greater the benefits a radiant barrier can offer.

Radiant barriers are more effective in hot climates than in cool climates, especially when cooling air ducts are located in the attic. Some studies show that radiant barriers can reduce cooling costs 5% to 10% when used in a warm, sunny climate. The reduced heat gain may even allow for a smaller air conditioning system. In cool climates, however, it’s usually more cost-effective to install more thermal insulation than to add a radiant barrier.

Types of Radiant Barriers:

Radiant barriers consist of a highly reflective material, usually aluminum foil, which is applied to one or both sides of a number of substrate materials such as kraft paper, plastic films, cardboard, oriented strand board, and air infiltration barrier material.

Some products are fiber-reinforced to increase durability and ease of handling.

Radiant barriers can be combined with many types of insulation materials in reflective insulation systems. In these combinations, radiant barriers can act as the thermal insulation’s facing material.

Some products are fiber-reinforced to increase durability and ease of handling.

Radiant barriers can be combined with many types of insulation materials in reflective insulation systems. In these combinations, radiant barriers can act as the thermal insulation’s facing material.

Frequently Asked Questions

How does cellulose insulation compare to other insulation types?

Cellulose insulation offers an R-value of approximately 3.8 per inch, which is comparable to fiberglass and rock wool. While spray foam has a higher R-value per inch, cellulose is significantly more affordable, making it a great choice for energy-efficient homes on a budget. It also performs better in sealing gaps around pipes and wires, reducing air infiltration.

What are the types of cellulose insulation available?

There are four main types of cellulose insulation:

- Dry cellulose (loose fill) is commonly used for retrofitting homes.

- Spray-applied cellulose is ideal for new construction, offering better seals and no settling issues.

- Low-dust cellulose has a dust dampener added, making it suitable for sensitive environments.

- Stabilized cellulose is typically used in attic insulation, reducing settling and weight.

Is cellulose insulation safe for my home?

Yes, cellulose insulation is safe for homes. It is made from 80% recycled newsprint and treated with borates to resist fire, mold, and pests. It is a “green” insulation option that provides excellent thermal and sound insulation. Additionally, its fire safety rating is Class I, which is the highest rating for fire resistance.

How does cellulose insulation improve energy efficiency?

Cellulose insulation significantly improves energy efficiency by reducing heat loss. It can help homeowners save 20-50% on their heating and cooling bills. The dense packing of cellulose limits air gaps and prevents convective air flows, making it a great choice for reducing heating costs during winter and cooling costs during summer.

How long does cellulose insulation last?

Cellulose insulation is durable and, when installed properly, can last for the life of the building. Unlike fiberglass, it doesn’t settle as much over time, especially with the dense-pack installation method. This ensures that it continues to provide excellent insulation performance for many years.