- 927 Lee Road 268, Valley, AL

- 256-790-9771

Spray Foam Insulation Attic Insulation Services by Pro Insulations

Thermal Imaging Services in East Alabama & West Georgia: Detect Heat Loss & Improve Energy Efficiency

Thermal Imaging Services in East Alabama & West Georgia: Detect Heat Loss & Improve Energy Efficiency

What Is Thermal Imaging?

Thermal imaging, also called thermography or thermal video, is the means by which humans may see in the infrared portion of the spectrum. One use includes finding where heat is escaping from a building.

Thermography finds many uses. One is where thermal insulation becomes faulty, building construction technicians can see heat leaks to improve the efficiency of cooling or heating air-conditioning.

Make the jump to energy efficiency today!

Spray foam insulation is the best choice for energy efficient insulation in your new or existing home.

Call us today

Types of Thermographic Inspection Devices

The energy auditor may use one of several types of infrared sensing devices in an on-site inspection.

A spot radiometer (also called a point radiometer) is the simplest. It measures radiation one spot at a time, with a simple meter reading showing the temperature of a given spot. The auditor pans the area with the device and notes the differences in temperature.

A thermal line scanner shows radiant temperature viewed along a line. The thermogram shows the line scan superimposed over a picture of the panned area. This process shows temperature variations along the line.

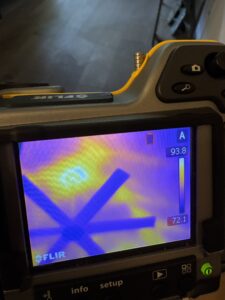

The most accurate thermographic inspection device is a thermal imaging camera, which produces a 2-dimensional thermal picture of an area showing heat leakage. Spot radiometers and thermal line scanners do not provide the necessary detail for a complete home energy assessment. Infrared film used in a conventional camera is not sensitive enough to detect heat loss.

The thermal imaging picture will show you exactly which areas of the building need to be improved.

The thermal imaging picture will show you exactly which areas of the building need to be improved.

Make the jump to energy efficiency today!

Spray foam insulation is the best choice for energy efficient insulation in your new or existing home.

Call us today

How Thermographic Inspections Work

Thermography measures surface temperatures by using infrared video and still cameras. These tools see light that is in the heat spectrum. Images on the video or film record the temperature variations of the building’s skin, ranging from white for warm regions to black for cooler areas. The resulting images help the auditor determine whether insulation is needed. They also serve as a quality control tool, to ensure that insulation has been installed correctly.

A thermographic inspection is either an interior or exterior survey. The energy auditor decides which method would give the best results under certain weather conditions. Interior scans are more common, because warm air escaping from a building does not always move through the walls in a straight line. Heat loss detected in one area of the outside wall might originate at some other location on the inside of the wall. Also, it is harder to detect temperature differences on the outside surface of the building during windy weather. Because of this difficulty, interior surveys are generally more accurate because they benefit from reduced air movement.

Thermographic scans are also commonly used with a blower door test running. The blower door helps exaggerate air leaking through defects in the building shell. Such air leaks appear as black streaks in the infrared camera’s viewfinder.

Thermography uses specially designed infrared video or still cameras to make images (called thermograms) that show surface heat variations. This technology has a number of applications. Thermograms of electrical systems can detect abnormally hot electrical connections or components. Thermograms of mechanical systems can detect the heat created by excessive friction. Energy auditors use thermography as a tool to help detect heat losses and air leakage in building envelopes.

Infrared scanning allows energy auditors to check the effectiveness of insulation in a building’s construction. The resulting thermograms help auditors determine whether a building needs insulation and where in the building it should go. Because wet insulation conducts heat faster than dry insulation, thermographic scans of roofs can often detect roof leaks.

In addition to using thermography during an energy assessment, you should have a scan done before purchasing a house; even new houses can have defects in their thermal envelopes. You may wish to include a clause in the contract requiring a thermographic scan of the house. A thermographic scan performed by a certified technician is usually accurate enough to use as documentation in court proceedings.

Frequently Asked Questions

How can thermal imaging help improve energy efficiency?

Thermal imaging helps identify areas in a building where heat is leaking. By detecting heat loss through walls, windows, or insulation, thermal imaging allows energy auditors to pinpoint areas needing improvement. Once these issues are addressed, energy efficiency can be significantly improved, reducing heating and cooling costs.

What are the different types of thermal imaging devices used for inspections?

Several types of thermal imaging devices are used for inspections:

- Spot Radiometer: This device measures temperature one spot at a time.

- Thermal Line Scanner: It measures temperature along a line, showing temperature variations.

- Thermal Imaging Camera: This provides a detailed 2D thermal picture of the building, helping to identify heat leakage more accurately than other devices.

Each device plays a role in detecting heat loss, with the thermal imaging camera being the most detailed and accurate option for energy assessments.

How does a thermal imaging inspection help detect insulation issues?

A thermal imaging inspection uses infrared cameras to detect temperature variations across a building’s surface. These temperature differences indicate areas where heat is escaping due to faulty insulation or air leaks. The resulting thermograms help energy auditors assess the effectiveness of existing insulation and determine where improvements are needed to enhance energy efficiency.

Can thermal imaging detect air leaks in my home?

Yes, thermal imaging is highly effective for detecting air leaks. When combined with a blower door test, thermal imaging can identify air leaks in the building envelope. The infrared camera captures these leaks as black streaks, allowing energy auditors to find and seal air leaks, ultimately improving the building’s energy efficiency.

Why should I choose thermal imaging for an energy assessment?

Thermal imaging provides a non-invasive, efficient method for detecting heat loss, insulation issues, and air leaks in a building. Unlike traditional methods, thermal imaging allows energy auditors to quickly pinpoint problem areas, saving time and improving the accuracy of the assessment. It’s a powerful tool for enhancing your home’s energy efficiency and lowering energy costs.